Toe boards, also known as toe kicks or toe guards, are essential in construction and safety. They prevent tools and materials from falling off edges and causing injuries.

But how high should toe boards be? Toe boards’ height is crucial for workplace safety. It ensures that objects do not slip off elevated surfaces. Most regulations require toe boards to be at least 4 inches high. This height provides a barrier to prevent objects from falling.

It’s important to follow these guidelines to maintain a safe environment. In this blog post, we will explore the standard heights for toe boards and why they are critical. Understanding this can help you ensure safety in your workplace. Let’s dive into the details and see how these simple structures make a big difference.

Introduction To Toe Boards

Ever wondered about those small barriers at the edge of scaffolding or platforms? These are toe boards, and they play a crucial role in construction safety. Toe boards are more than just a safety feature—they are a necessity. Understanding their purpose and application can make a significant difference in workplace safety. Let’s dive into the essential details about toe boards.

Purpose Of Toe Boards

Toe boards are designed to prevent tools, materials, or debris from falling off elevated surfaces. This is crucial in construction sites where workers operate at various heights. Imagine a wrench slipping off a platform and hitting someone below—toe boards help prevent such incidents.

They also serve as a visual boundary, reminding workers of the platform’s edge. This reduces the risk of accidental slips and falls. By providing this dual protection, toe boards ensure a safer working environment for everyone involved.

Common Uses In Construction

In the construction industry, toe boards are commonly installed on scaffolding, mezzanines, and rooftops. They are a standard feature wherever there’s a risk of falling objects. Construction sites are dynamic environments, and toe boards adapt to various setups and needs.

Toe boards aren’t just limited to construction. They’re used in warehouses, factories, and any place where elevated work areas are present. Their versatility is a testament to their importance in maintaining workplace safety.

Have you ever been on a site where toe boards made you feel more secure? Their presence is a simple yet effective measure that underscores the importance of attention to detail in safety protocols.

Next time you see a toe board, consider the peace of mind it provides. It’s a small feature with a big impact on safety. What measures do you take to ensure safety in your workspace?

Credit: www.teacherspayteachers.com

Regulations And Standards

Toe boards are crucial safety barriers in construction and industry. Typically, they must be at least 4 inches high. This standard height helps prevent tools or materials from falling, ensuring worker safety.

Understanding the regulations and standards surrounding toe boards is crucial for maintaining workplace safety. These boards, also known as kickboards, prevent tools and materials from falling off elevated surfaces, which can pose significant risks. To ensure safety, specific guidelines are in place, varying from one region to another. Are you aware of the standards that might affect your workplace? Let’s dive into the details.Osha Requirements

The Occupational Safety and Health Administration (OSHA) sets clear standards for toe boards in the United States. According to OSHA, a toe board must be at least 3.5 inches high. This measurement ensures that tools and debris are effectively blocked from falling over the edge. In addition to height, OSHA mandates that toe boards withstand a force of at least 50 pounds. This requirement ensures durability and reliability. Have you ever considered how much force a simple tool might exert when accidentally kicked off a platform?International Guidelines

Regulations can vary significantly outside the United States. In Europe, for instance, the European Union standards often require toe boards to be at least 4 inches high. This slight difference highlights the importance of understanding local regulations. Countries like Australia and Canada might have different specifications. While the basic purpose remains the same, the standards can differ in dimensions and materials. It’s essential to review the guidelines specific to your region to ensure compliance. Understanding these regulations can be the difference between a safe environment and potential hazards. Have you checked if your workplace toe boards meet the necessary requirements? Ensure you’re not just following the rules but actively creating a safer workspace for everyone.Toe Board Dimensions

Understanding the dimensions of toe boards is crucial for ensuring safety in construction and other industrial settings. The dimensions, including height, material, and other specifications, directly impact their effectiveness in preventing accidents. Let’s delve into the key aspects of toe board dimensions.

Height Specifications

The height of toe boards is a critical factor. Generally, toe boards should be at least 4 inches tall. This height is typically sufficient to prevent tools and materials from falling off the edge of platforms.

However, certain environments may require taller toe boards. For instance, areas with larger tools may benefit from toe boards that are 6 inches or higher. Always check the local safety regulations to ensure compliance.

Material Considerations

Toe boards come in various materials, each with its own set of advantages. Wood is a common choice due to its affordability and ease of installation.

Metal toe boards offer greater durability and are ideal for heavy-duty environments. They are less prone to damage and can withstand harsh conditions better than wood.

Plastic toe boards are lightweight and resistant to corrosion. They are suitable for environments where exposure to moisture or chemicals is a concern.

Choosing the right material depends on the specific needs of your project. Consider factors such as durability, cost, and environmental conditions when making your decision.

Have you ever worked in an environment where the toe boards didn’t seem adequate? What adjustments did you make to ensure safety?

Credit: www.vsathletics.com

Safety Benefits

Toe boards are typically 4 inches high. They prevent tools and materials from falling. This helps keep workers safe.

When considering the safety of a construction site or any elevated work area, toe boards play a critical role. They are simple yet effective barriers that provide essential safety benefits. These boards, typically a few inches high, are installed at the edge of platforms, scaffolds, and other elevated workspaces. Their primary purpose is to prevent accidents and improve workplace safety.Preventing Falls

Imagine working at a height, focusing on your task, and a simple misstep could lead to a dangerous fall. Toe boards act as a physical barrier, reducing the risk of stepping off the edge. They provide a clear boundary, making it easier for you to stay within safe limits. Falls can lead to severe injuries or even fatalities. By having toe boards in place, you minimize these risks significantly. They serve as a constant visual reminder of the edge, promoting cautious movement.Containing Tools And Materials

Ever had a wrench or a hammer fall from your work platform? It can be both dangerous and costly. Toe boards help keep tools and materials contained within the workspace. This prevents them from being accidentally kicked off. Loose materials falling from a height can injure someone below. Toe boards ensure that your tools stay in place, reducing the risk of accidents. They also save you the hassle of retrieving fallen items, keeping your workflow smooth. Reflect on the times you’ve had to pause work to fetch a dropped tool. Toe boards eliminate these interruptions, enhancing productivity. They keep everything where it should be, allowing you to focus on the task at hand. Do you have toe boards installed in your work area? If not, consider the safety benefits they offer. Simple adjustments can create a safer and more efficient workspace for everyone involved.Installation Best Practices

Toe boards typically stand at least 4 inches high on platforms. This height prevents tools and materials from falling off. Essential for safety, toe boards help protect workers below from potential hazards.

When installing toe boards, ensuring they are set up correctly is crucial for safety and stability. Good installation practices can prevent accidents and prolong the life of the boards. This section will guide you through the essentials of installing toe boards effectively, focusing on key elements like securing them and maintaining their structural integrity.Securing Toe Boards

Properly securing toe boards is the first step in a solid installation. Ensure they are fastened tightly to the base structure. Loose boards can lead to accidents and may not meet safety standards. Use screws or nails that are appropriate for the material of your toe boards. Stainless steel screws are often recommended for their durability and resistance to rust. Make sure the fasteners are spaced evenly along the board to distribute weight and stress. Ask yourself: Are the boards firmly attached, or is there room for movement? A little time spent double-checking security can save you from costly repairs or safety breaches.Maintaining Structural Integrity

Maintaining the structural integrity of your toe boards is vital for long-term safety and function. Regularly inspect them for signs of wear or damage. If a board is cracked or split, replace it immediately to avoid further issues. Choose materials that withstand the conditions they’ll face. For outdoor installations, consider treated wood or metal, which can handle moisture and temperature changes without degrading. Have you considered the impact of environmental factors on your boards? Regular maintenance checks can ensure your toe boards continue to perform effectively, safeguarding the areas they protect. Taking the time to install toe boards correctly not only boosts safety but also reduces future maintenance needs. By securing them properly and maintaining their integrity, you ensure a durable setup that stands the test of time.Common Challenges

Toe boards are crucial for safety on construction sites. They prevent tools and materials from falling. However, toe boards face several challenges affecting their effectiveness. Understanding these challenges helps in maintaining their integrity and functionality.

Weather Impact

Weather greatly affects toe boards. Rain can cause them to rot or rust. This weakens their structure over time. In areas with heavy snowfall, toe boards can get buried. Snow weight can cause damage, requiring frequent checks and maintenance.

Wear And Tear

Frequent use leads to wear and tear. Workers often bump into them. Equipment may collide with them. These incidents cause dents and scratches. Over time, these small damages accumulate. They weaken the board’s protective capability. Regular inspection and repair are essential.

Innovations In Toe Board Design

In the world of construction and safety, toe boards play a pivotal role in preventing tools and materials from falling off elevated surfaces. As safety standards evolve, so does the design of toe boards. The latest innovations aim to enhance functionality and adaptability, making them indispensable for modern work environments. Let’s explore how these advancements are shaping the future of toe boards.

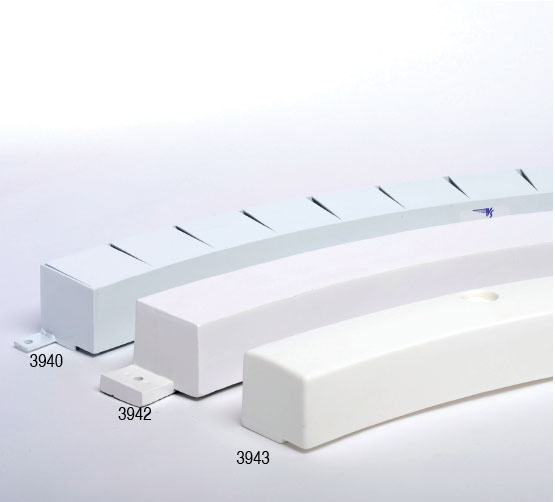

Adjustable Toe Boards

Imagine working on a site where you need different heights for toe boards depending on the task. Adjustable toe boards are your solution. These designs allow you to change the height easily to suit various requirements. This flexibility ensures that you can maintain safety without compromising on efficiency.

Picture this: you’re on a construction site, and the team is moving from a high platform to a lower one. With adjustable toe boards, a simple tweak can make the transition seamless. This adaptability reduces downtime and boosts productivity. It’s like having a tool that grows with your needs.

Durable Materials

Gone are the days when toe boards wore out quickly. Innovations now focus on using materials that withstand harsh conditions. Steel and reinforced plastics are leading the way. These materials promise longevity and reduce the need for frequent replacements.

Consider the benefit of using durable materials. Not only do they offer peace of mind, but they also save money in the long run. You invest once and enjoy reliable performance for years. This is crucial, especially in environments where safety and cost-effectiveness are paramount.

Have you ever wondered how toe boards can evolve further? Imagine a future where they are integrated with smart technology, alerting you when maintenance is due. The possibilities are endless, and staying informed about these innovations can help you make the best choices for your projects.

Case Studies

Exploring the height of toe boards, this case study reveals essential safety standards. Toe boards typically stand at least four inches tall. Ensuring proper height protects workers from falling objects and accidents on job sites.

When it comes to workplace safety, toe boards play a critical role. These low barriers are often overlooked, yet they are vital in preventing tools and materials from falling onto workers below. Understanding their importance becomes evident through real-world case studies. Let’s explore some practical examples and insights drawn from both successful implementations and lessons learned from accidents.Successful Implementations

One factory in Texas took proactive measures by installing toe boards along all elevated platforms. Within months, the number of dropped tools incidents reduced drastically. Workers felt safer, knowing that even small items wouldn’t fall unexpectedly. In another example, a construction company introduced toe boards on scaffolding after a safety audit. The change resulted in fewer injuries and improved morale. Workers appreciated the added security, which led to increased productivity. Such success stories highlight the importance of toe boards in creating a safer work environment. Have you considered how toe boards might benefit your workplace?Lessons Learned From Accidents

A recent accident in an urban construction site underscored the necessity of toe boards. A wrench fell from a high platform, injuring a worker below. The investigation revealed that toe boards could have prevented the accident. This incident led to a company-wide policy change. Toe boards became mandatory on all elevated surfaces, reducing future risks. It’s a stark reminder that sometimes, simple solutions can prevent serious accidents. Another case involved a warehouse where toe boards were improperly installed. A small gap allowed items to fall, resulting in multiple injuries. Corrective action was swift, but the lesson was clear: thorough installation and regular inspections are crucial. These cases illustrate the consequences of neglecting toe board installation. How can you ensure that your workplace doesn’t repeat these mistakes? By examining these case studies, you gain valuable insights into the real-world application of toe boards. Prioritizing their use could be the key to creating a safer environment for everyone. Are toe boards part of your safety checklist?

Credit: www.amazon.com

Frequently Asked Questions

How High Should A Toeboard Be?

A toeboard should be at least 4 inches high to comply with safety standards.

What Is The Standard Height Of A Toe Guard?

The standard height of a toe guard typically ranges from 1 to 1. 5 inches. This height offers protection while maintaining comfort and functionality for various footwear types. Ensure the toe guard fits well for optimal safety and performance.

What Is The Standard Size Of A Toe Board?

The standard size of a toe board is 4 inches high. It prevents tools and materials from falling off edges. Toe boards are commonly used in construction for safety. They ensure compliance with OSHA regulations and enhance workplace security. Proper installation of toe boards is crucial to avoid accidents.

What Is The Height Of The Shot Put Toe Board?

The height of the shot put toe board is 10 centimeters. It is designed to ensure fair competition. The board helps athletes maintain proper form.

Conclusion

Toe boards play a crucial role in workplace safety. They prevent tools and materials from falling. This ensures a safer environment for everyone. Always check the height and placement of toe boards. Consistent maintenance and inspection are key. Proper toe board usage can reduce accidents.

Prioritize safety and stay vigilant.