Formwork is a temporary structure used in construction. It shapes and supports concrete until it hardens.

Formwork is essential in the construction industry. It ensures that concrete structures are built correctly. The process involves creating molds with wood, metal, or other materials. These molds hold the concrete in place while it sets. Without formwork, concrete could not form the desired shapes.

This technique is vital for building foundations, walls, and other concrete structures. Understanding formwork helps in planning and executing construction projects. It’s a fundamental skill for builders and engineers. Let’s explore the different types and uses of formwork in construction.

Introduction To Formwork

Formwork is an essential part of modern construction. It involves creating temporary molds to hold wet concrete until it hardens. These molds ensure the concrete sets in the desired shape and size. Understanding formwork is crucial for any construction project.

Basics Of Formwork

Formwork consists of various materials like wood, steel, and aluminum. Wood is common due to its ease of use. Steel and aluminum are reusable, making them cost-effective. The primary purpose is to shape and support concrete structures.

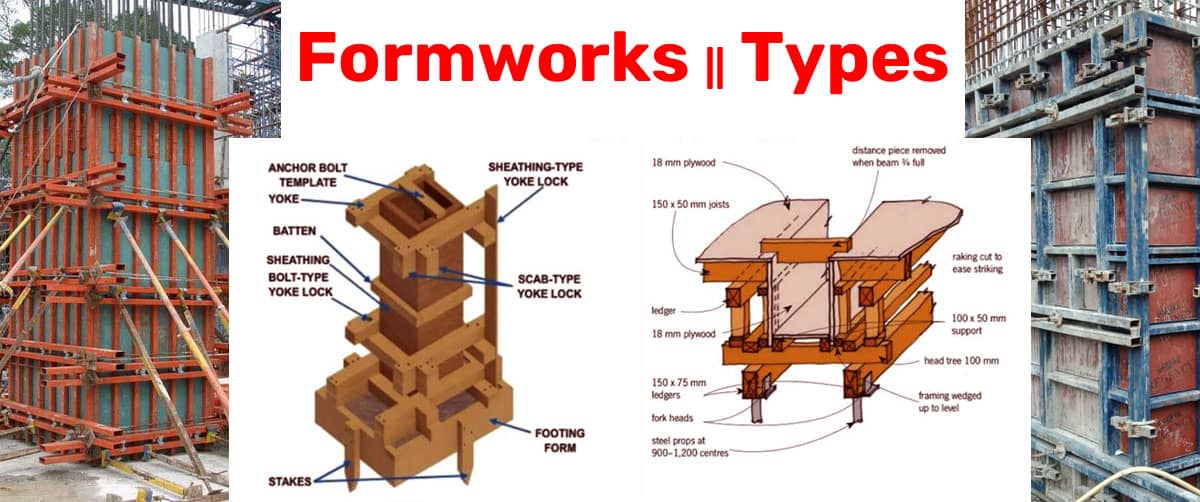

Types of formwork include traditional timber, engineered formwork systems, and stay-in-place formwork. Each type serves different construction needs. Engineers select the best type based on project requirements.

Importance In Construction

Formwork is vital for structural integrity. It ensures concrete sets correctly and safely. Proper formwork reduces errors and delays. It also enhances the quality of the finished structure.

Accurate formwork improves project efficiency. It lowers costs by minimizing waste and rework. Skilled labor is needed for formwork, ensuring safety and precision. Formwork is the backbone of successful construction projects.

Types Of Formwork

Formwork is essential in construction. It provides the mold for concrete, ensuring it hardens into the desired shape. Various types of formwork exist, each with unique benefits. Understanding these types helps you choose the best option for your project.

Timber Formwork

Timber formwork is the oldest type. It uses wood as the primary material. This type is cost-effective and easy to produce. It can be cut into any shape and size, making it versatile.

- Easy to install and remove

- Lightweight and easy to handle

- Suitable for small projects

Despite its benefits, timber formwork has a short lifespan. It can warp and absorb moisture, affecting its durability.

Steel Formwork

Steel formwork is more durable than timber. It is strong and can be reused many times. Steel formwork is perfect for large projects requiring a high-quality finish.

- Long-lasting and reusable

- Provides a smooth finish

- Resistant to moisture and warping

The downside is that steel formwork is heavy and costly. It requires skilled labor to set up and dismantle.

Aluminum Formwork

Aluminum formwork is lightweight and easy to handle. It offers the same strength and durability as steel. This type is suitable for repetitive use, making it ideal for large-scale projects.

- Lightweight and easy to transport

- Durable and reusable

- Provides a smooth and high-quality finish

Aluminum formwork can be more expensive than timber but offers better long-term value due to its reusability.

Plastic Formwork

Plastic formwork is a modern alternative. It is lightweight, easy to handle, and resistant to moisture. This type is cost-effective and suitable for small to medium projects.

- Lightweight and easy to assemble

- Resistant to moisture and corrosion

- Reusable and eco-friendly

Plastic formwork is less durable than steel and aluminum. It can crack under heavy loads, limiting its use in large projects.

| Type | Material | Advantages | Disadvantages |

|---|---|---|---|

| Timber Formwork | Wood | Cost-effective, easy to produce | Short lifespan, absorbs moisture |

| Steel Formwork | Steel | Durable, reusable | Heavy, costly |

| Aluminum Formwork | Aluminum | Lightweight, durable | Expensive |

| Plastic Formwork | Plastic | Lightweight, moisture-resistant | Less durable, can crack |

Formwork Systems

Formwork systems are essential in the construction industry. They provide temporary molds to hold concrete in place while it hardens. There are various types of formwork systems, each designed to suit different construction needs. Understanding these systems can help in selecting the right method for your project.

Traditional Systems

Traditional formwork systems are often made from timber or plywood. These materials are easy to work with and can be customized for different shapes.

- Timber Formwork: Flexible and adaptable, suitable for small projects.

- Plywood Formwork: Strong and durable, used for repetitive tasks.

Traditional systems are cost-effective but labor-intensive. They require skilled labor to assemble and dismantle. This can increase construction time.

Engineered Systems

Engineered formwork systems use prefabricated modules, often made from steel or aluminum. These systems are designed for efficiency and precision.

| System Type | Material | Advantages |

|---|---|---|

| Steel Formwork | Steel | Durable, reusable, and suitable for high-rise buildings. |

| Aluminum Formwork | Aluminum | Lightweight, easy to handle, and fast to assemble. |

Engineered systems reduce labor costs and construction time. They offer high-quality finishes and can be reused multiple times, making them cost-effective in the long run.

Credit: civilguidelines.com

Materials Used In Formwork

Formwork is a critical part of construction. It shapes and supports the concrete until it hardens. The materials used in formwork affect the quality, cost, and efficiency of the project. Here are some common materials used in formwork:

Wood

Wood is one of the most traditional materials for formwork. It is easy to cut and shape. This makes wood a versatile choice. Builders often use timber for smaller projects. It is lightweight and easy to handle. However, wood can absorb moisture, which may affect the concrete.

Metal

Metal formwork is strong and durable. Common metals used include steel and aluminum. These materials are excellent for large projects. They can withstand high pressure and can be reused many times. This makes metal formwork cost-effective in the long run. It provides a smooth finish to the concrete surface.

Plastic

Plastic formwork is gaining popularity. It is lightweight and easy to clean. Plastic formwork is also resistant to water and chemicals. This makes it a good choice for projects exposed to harsh conditions. It is less likely to warp or absorb moisture compared to wood.

Composite Materials

Composite materials combine different substances to enhance their properties. Examples include fiberglass and carbon fiber. These materials are strong and lightweight. They are also resistant to corrosion and wear. Composite formwork is ideal for complex designs and repetitive use. It offers high precision and a smooth finish.

| Material | Advantages | Disadvantages |

|---|---|---|

| Wood | Easy to cut and shape, Lightweight | Absorbs moisture, Less durable |

| Metal | Durable, Reusable, Smooth finish | Heavy, Higher initial cost |

| Plastic | Lightweight, Water-resistant, Easy to clean | Can be less strong than metal |

| Composite | Strong, Lightweight, Corrosion-resistant | Higher cost, Limited availability |

Design Considerations

Formwork is a crucial element in construction, ensuring structures are built correctly. Design considerations play a vital role in determining the success and efficiency of formwork. Three key aspects to keep in mind are load bearing capacity, flexibility and adaptability, and surface finish requirements.

Load Bearing Capacity

The load bearing capacity of formwork is essential for structural stability. It must support the weight of fresh concrete and any additional loads. These could include workers, machinery, or environmental factors. Ensuring adequate load bearing capacity prevents accidents and structural failures.

Consider using high-strength materials like steel or aluminum. These provide better support compared to traditional wood formwork. Properly designed formwork also minimizes deflection and deformation during the concrete curing process.

Flexibility And Adaptability

Flexibility and adaptability are crucial for efficient formwork design. Construction projects often have unique shapes and sizes. Formwork should easily adapt to these variations. Modular formwork systems offer great flexibility. They can be adjusted and reused for different projects.

Using modular systems can also reduce costs and construction time. They are easier to assemble and disassemble. This makes them ideal for projects with tight schedules. Versatile formwork systems contribute to overall construction efficiency.

Surface Finish Requirements

The surface finish of the concrete is often as important as its structural integrity. Formwork must provide a smooth and uniform finish. This is especially true for visible surfaces. Different materials can affect the final appearance. For example, steel formwork often results in a smoother finish than wood.

To achieve the desired surface finish, use high-quality formwork materials. Ensure the formwork is clean and free of debris. Properly treated formwork can also reduce the need for additional surface treatments. This saves time and resources.

Formwork Construction Process

The formwork construction process is crucial in building structures. It involves creating molds to hold wet concrete until it hardens. This process ensures that the concrete sets in the desired shape and strength. Let’s explore the key stages of the formwork construction process.

Planning And Design

First, planning and design play a vital role. Engineers create detailed blueprints. These plans outline the formwork layout and materials. Proper planning ensures efficiency and safety. It also helps in estimating costs and resources.

Assembly And Erection

Next, assembly and erection of the formwork take place. Workers gather materials like timber, steel, or plastic. They assemble the formwork according to the blueprints. This stage requires precision to avoid errors. Proper assembly ensures the structure’s integrity.

Inspection And Quality Control

Inspection and quality control are critical steps. Inspectors check the formwork for alignment and stability. They ensure that all components are secure. Regular inspections prevent accidents and ensure high-quality construction. Quality control guarantees that the finished structure meets all standards.

Safety Measures

Formwork is a crucial part of construction. It involves creating molds to hold wet concrete in place until it hardens. Safety measures are essential during this process to protect workers, ensure structural integrity, and minimize environmental impact.

Worker Safety

Ensuring worker safety is vital. Workers must wear protective gear such as helmets, gloves, and safety boots. Regular safety training is also important. It helps workers handle tools and materials safely. Keeping the work area clean reduces the risk of accidents. Scaffolding must be stable and secure. Inspections should be frequent.

Structural Safety

Structural safety is another key aspect. Formwork must be strong enough to hold the weight of the wet concrete. The design should follow engineering standards. Using high-quality materials ensures durability. Support systems should be checked regularly. Proper alignment is necessary to avoid structural failures.

Environmental Safety

Environmental safety should not be overlooked. Using eco-friendly materials helps reduce the environmental impact. Waste management is crucial. Dispose of debris properly to keep the site clean. Implementing recycling practices can also be beneficial. Minimizing noise and dust pollution protects the surrounding area.

Credit: meva.net

Cost And Efficiency

Cost and efficiency play a significant role in construction. Formwork helps manage these aspects effectively. It offers various benefits that contribute to lower costs and increased efficiency.

Cost-effective Solutions

Formwork systems help reduce construction costs. They use materials that are affordable and easy to source. This reduces the overall budget. Prefabricated formwork systems are reusable. This further reduces costs. Contractors can use them multiple times. This means they do not need to buy new materials for each project.

Time-saving Techniques

Formwork speeds up construction projects. It provides a ready structure for concrete. This speeds up the building process. Prefabricated formwork is quick to set up. It saves hours compared to traditional methods. Less time spent on setup means projects finish faster. This leads to cost savings and more efficient use of resources.

Sustainability And Reusability

Formwork contributes to sustainability in construction. Many formwork systems are reusable. This reduces waste and conserves resources. Wood, steel, and aluminum are common materials. These materials are durable and recyclable. Using reusable formwork aligns with eco-friendly building practices. This benefits both the environment and project budget.

Innovations In Formwork

Formwork plays a crucial role in construction. It shapes the concrete until it hardens. Innovations in formwork have transformed the industry. These advancements improve efficiency, safety, and quality.

Technological Advancements

Recent technological advancements have streamlined formwork processes. Digital tools and software aid in design and planning. 3D modeling helps visualize complex structures. Advanced materials enhance strength and durability. Robotics and automation reduce manual labor. Sensors monitor concrete curing and quality.

Modern Techniques

Modern techniques in formwork focus on sustainability. Reusable formwork systems reduce waste. Lightweight materials make handling easier. Modular formwork allows quick assembly and disassembly. Self-climbing formwork adapts to tall structures. Insulating formwork systems improve energy efficiency.

Credit: theconstructor.org

Frequently Asked Questions

What Is Formwork Used For?

Formwork is used to mold concrete into specific shapes. It provides support until the concrete hardens.

What Materials Are Used In Formwork?

Formwork can be made from timber, steel, aluminum, or plastic. The choice depends on the project requirements.

How Long Does Formwork Stay In Place?

Formwork typically stays in place until the concrete is strong enough. This usually takes 7 to 14 days.

What Are The Types Of Formwork?

There are several types including traditional timber formwork, engineered formwork systems, and re-usable plastic formwork.

Conclusion

Formwork is crucial in construction. It shapes concrete into desired forms. Proper formwork ensures strength and stability. It also speeds up construction time. Different types of formwork suit various projects. Choosing the right formwork enhances quality and efficiency. Proper maintenance extends formwork life.

Understanding formwork basics benefits builders and project managers. This knowledge helps in making informed decisions. Always prioritize safety and quality in formwork use.